I had the great pleasure to spend the first part of the week working with Bruce Lane of Precision Measurements, pushing really hard on the ground and measuring really carefully. I was in Portland, Oregon validating a simple but innovative ground improvement design before greenlighting production installation.

The project is a classic Pearl District apartment building, 5 stories of wood-framed residential over 1.5 levels of concrete basement. Soils at the site are pretty soft, but good dense gravel is available shallow enough that driving piles seemed excessive. Working with DeWitt Construction, Atlas Geotechnical designed a system of low-strength concrete shafts that improved the bearing capacity enough to support the building on footings instead of costly piles.

Engineering, especially innovative engineering, is all about getting the details right. All of the details, not just to obvious or convenient ones. Bruce is an indispensable part of confirming that the concrete shafts behave the way that we predicted in the design.

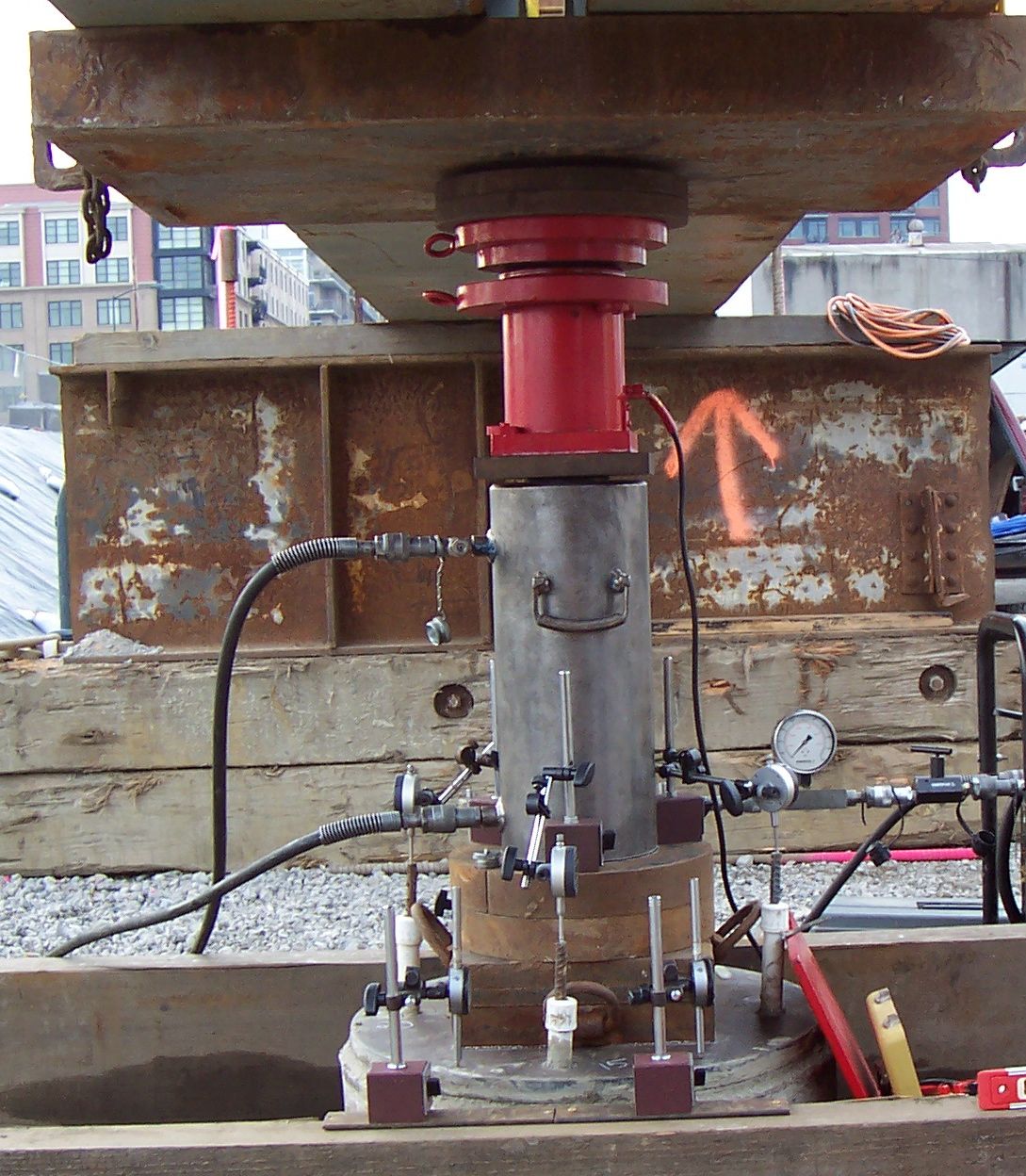

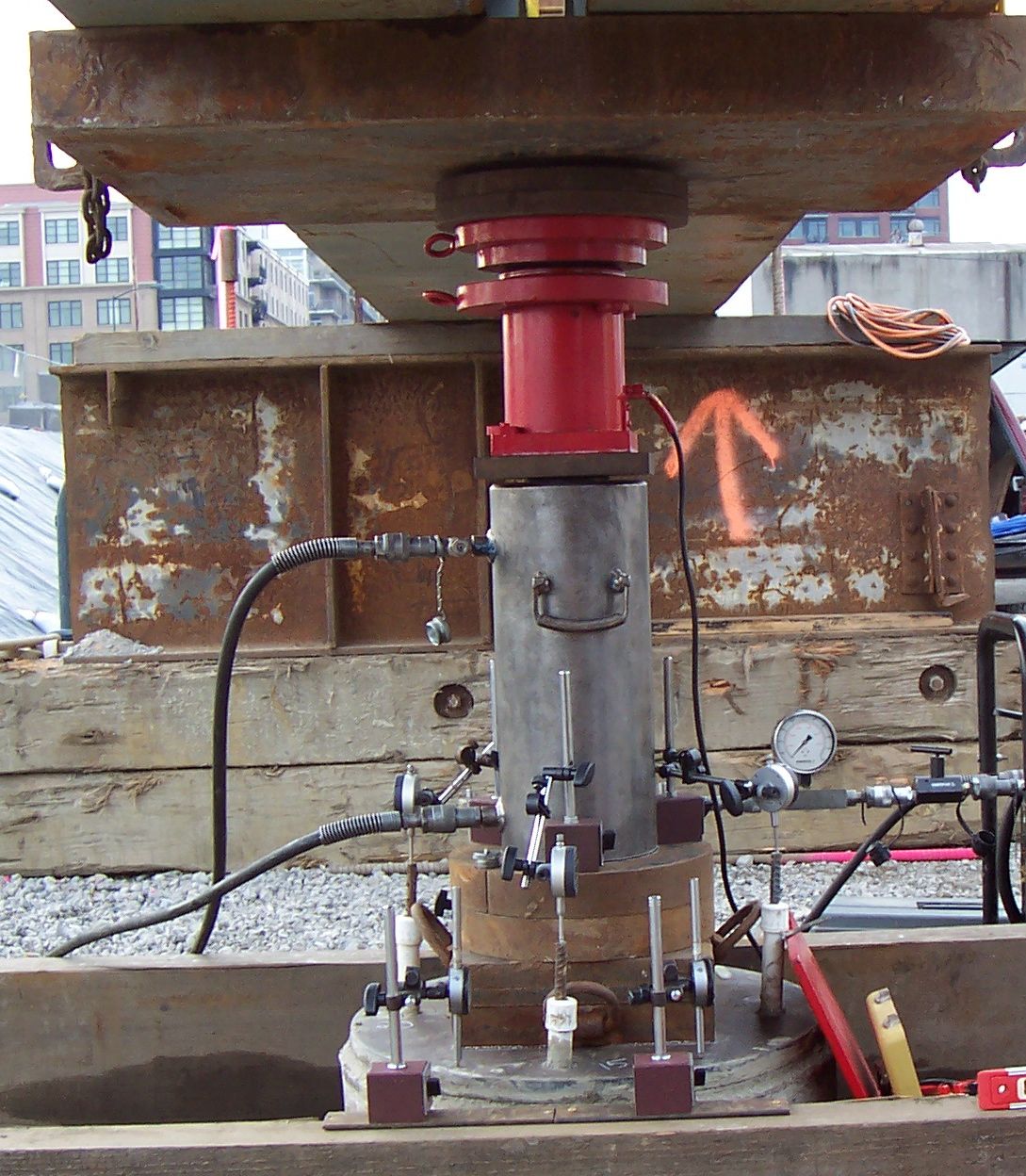

Bruce is one of those rare individuals capable of performing very sensitive work very accurately away from a controlled laboratory setting. This set of skills is slightly more common where we practice, in the heavy infrastructure industry, but is by no means common. You know you are working with professionals committed to quality when they tell you about how they stripped and waxed their hydraulic cylinders because the paint was always chipped and looked shabby in the report photographs. Of course the data needed to be complete and correct, and standard procedures rigorously followed, but taking the time to polish the equipment for photos indicates a commitment to excellence that seemed very familiar to us here at Atlas.

Bruce has the skill, experience, equipment, and patience to get the kind of high-quality data that instills confidence in a design, allowing safety factors to stay in the acceptable range and construction to proceed apace. And if you ever do have an unexpected result, Bruce can identify the cause while it’s developing, often modifying the test procedure to collect insightful measurements, so you know where to focus your attention when revising the design. This is a crucial aspect of the “Observational Method” that forms the backbone of Atlas Geotechnical’s expertise, and in fact is one of the most difficult to obtain.

We had great success with the validation program, demonstrating the necessary strength and stiffness while also seeing real failures that demonstrate we didn’t have excessive conservatism in our design. We even had a failure, but of a reaction element and not the test element itself, that Bruce caught before the reaction frame became unstable and dangerous. Working with Bruce, the DeWitt Crew, and really everyone on The Parker project made for two excellent days of work, and having bright sunshine in February, good friends extending hospitality, and really excellent beer after work made the trip an overall brilliant experience.